China Compulsory Product Certification Certificate

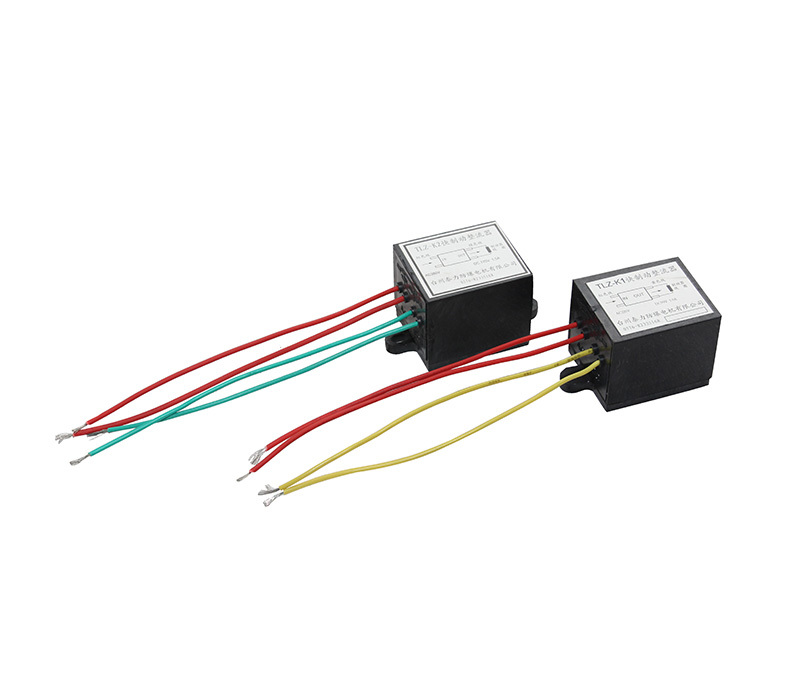

The AC brake has a fast starting response, short braking time, and adjustable reliable braking torque

Product serial number:

1363799741120008192

Category:

Keyword: China Compulsory Product Certification Certificate

- Product Description

-

- Commodity name: China Compulsory Product Certification Certificate

- Commodity ID: 1363799741120008192

Related Products

Message

If you have any questions, please contact us!