DZK series electromagnetic brake

The AC brake has a fast starting response, short braking time, and adjustable reliable braking torque

Product serial number:

Category:

Keyword: DZK series electromagnetic brake

- Product Description

- Technical parameters

- Appearance and installation dimensions

- Installation and debugging

- Common faults and troubleshooting

- Sample and video download

-

- Commodity name: DZK series electromagnetic brake

Product Introduction

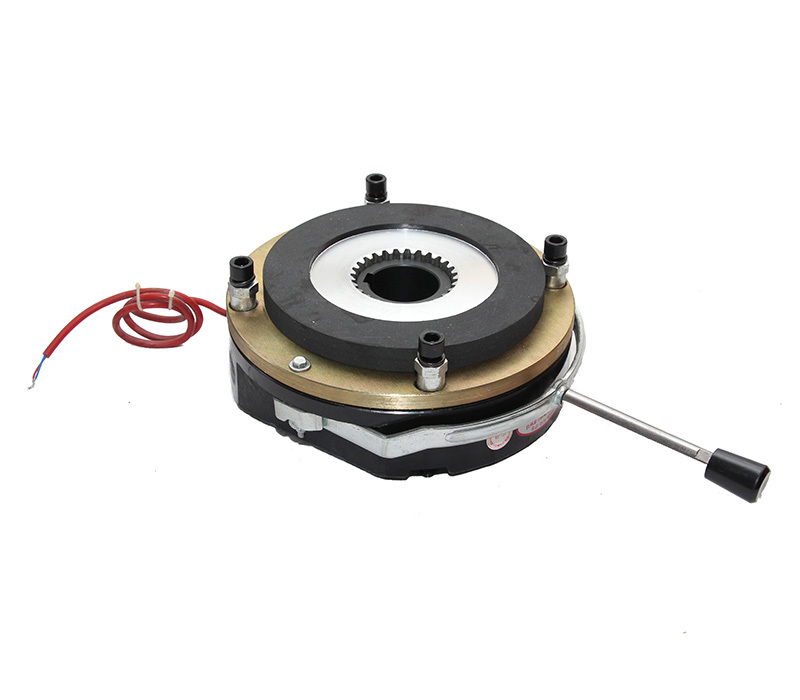

The DZK series (de-energized type) DC electromagnetic brake is a reliable brake. The product has a compact structure, convenient and flexible manual release, and reliable performance.

The DZK series brake is matched with the Y2 series motor to form the YEJK series electromagnetic braking three-phase asynchronous motor. The motor has a beautiful appearance, fast braking, accurate positioning, and is suitable for all occasions where motors are used.

Working Principle

When energized, the electromagnet generates a strong electromagnetic force to attract the armature plate, compressing the brake spring. The two mating surfaces of the brake disc are separated from the pressure of the armature plate and the motor rear cover plane, allowing the motor to rotate freely. When de-energized, the brake spring pressure is applied to the armature plate, pressing it tightly against the brake disc, generating a strong frictional braking torque, causing the rotating motor to brake quickly and achieve accurate positioning.

Product Features

1. The overall protection level reaches IP23;

2. Manual release is an external handle, flexible and convenient;

3. Insulation class is F;

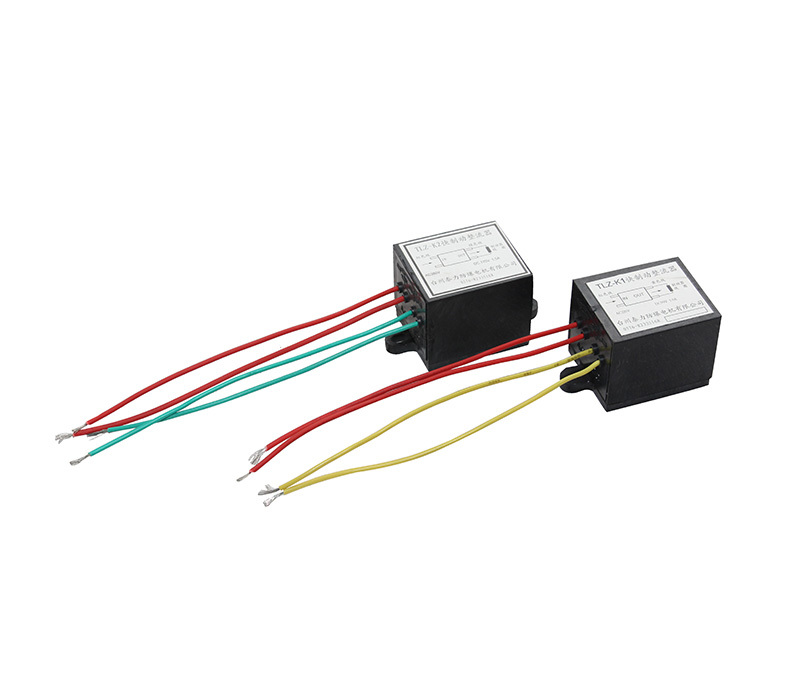

Matching Components Supply

For the convenience of our customers in using the DZK series DC electromagnetic brake, in addition to providing matching rear covers, junction boxes, windshields, rectifiers and other accessories, our company also provides drawings for processing rotors of corresponding specifications. As long as they are processed according to our drawings, YEJK series brake motors can be produced.

-

-

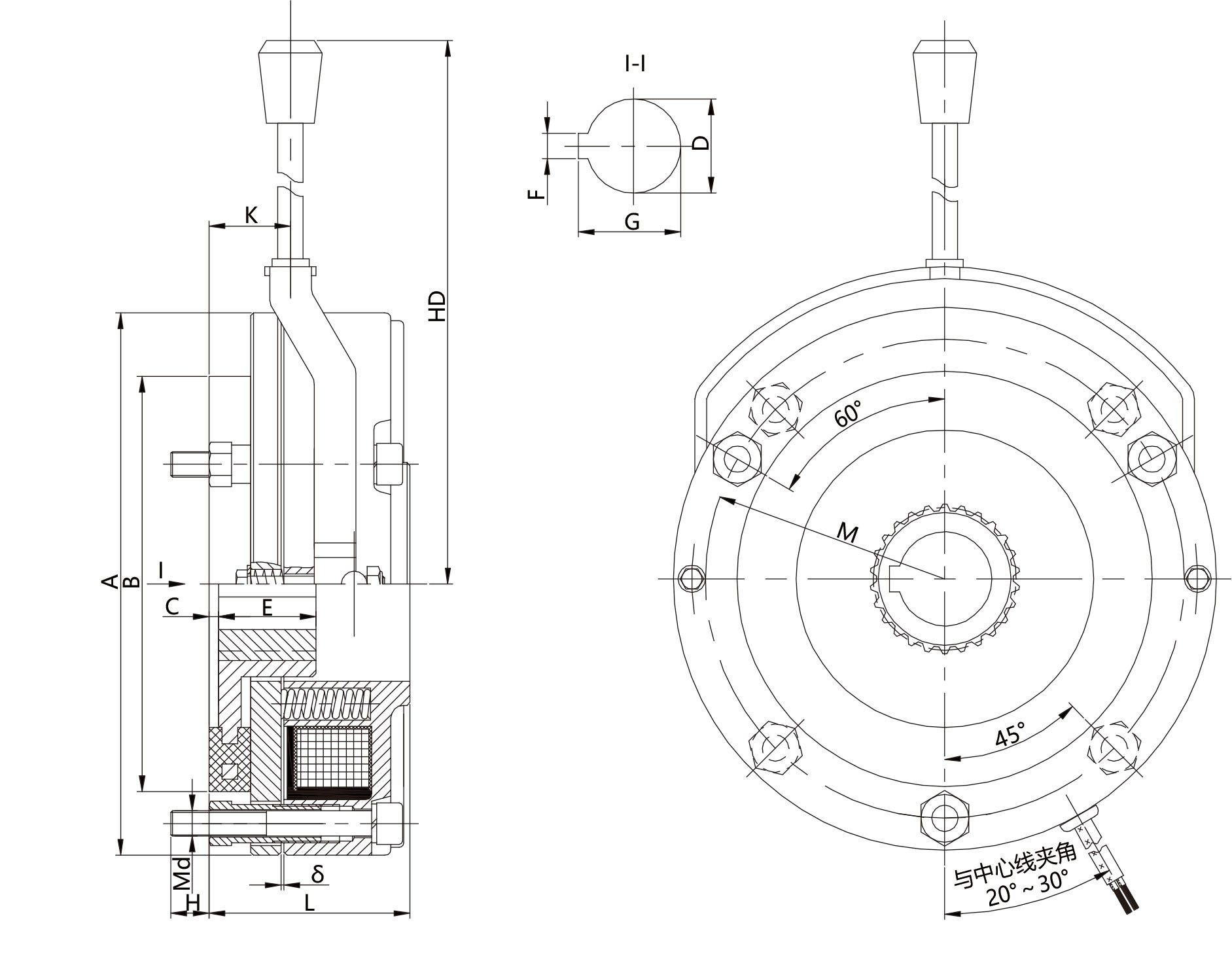

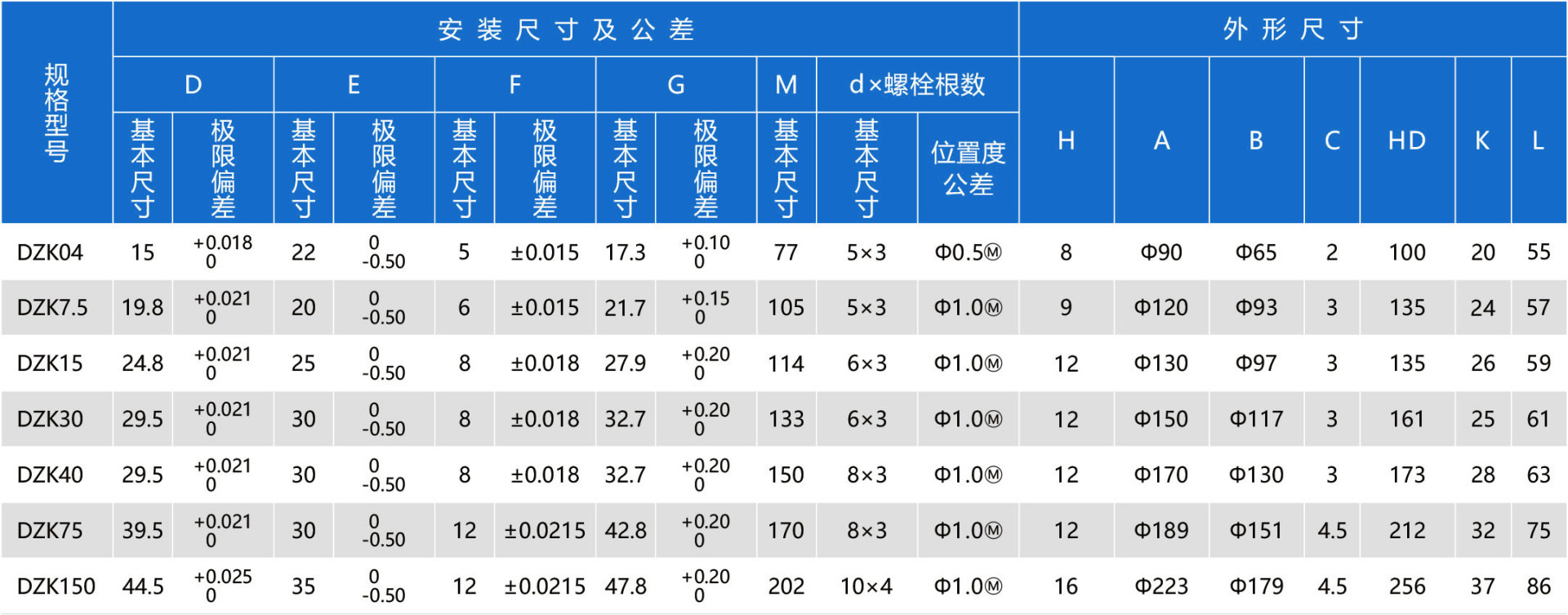

Note: Specifications DZK04~DZK75, S holes (solid line) 3 × 120°, and DZK04 three holes are in an equilateral triangle distribution, DZK7.5~DZK75 are in an inverted triangle distribution. Specification DZK150, S holes (dashed line) 4 × 90°.

-

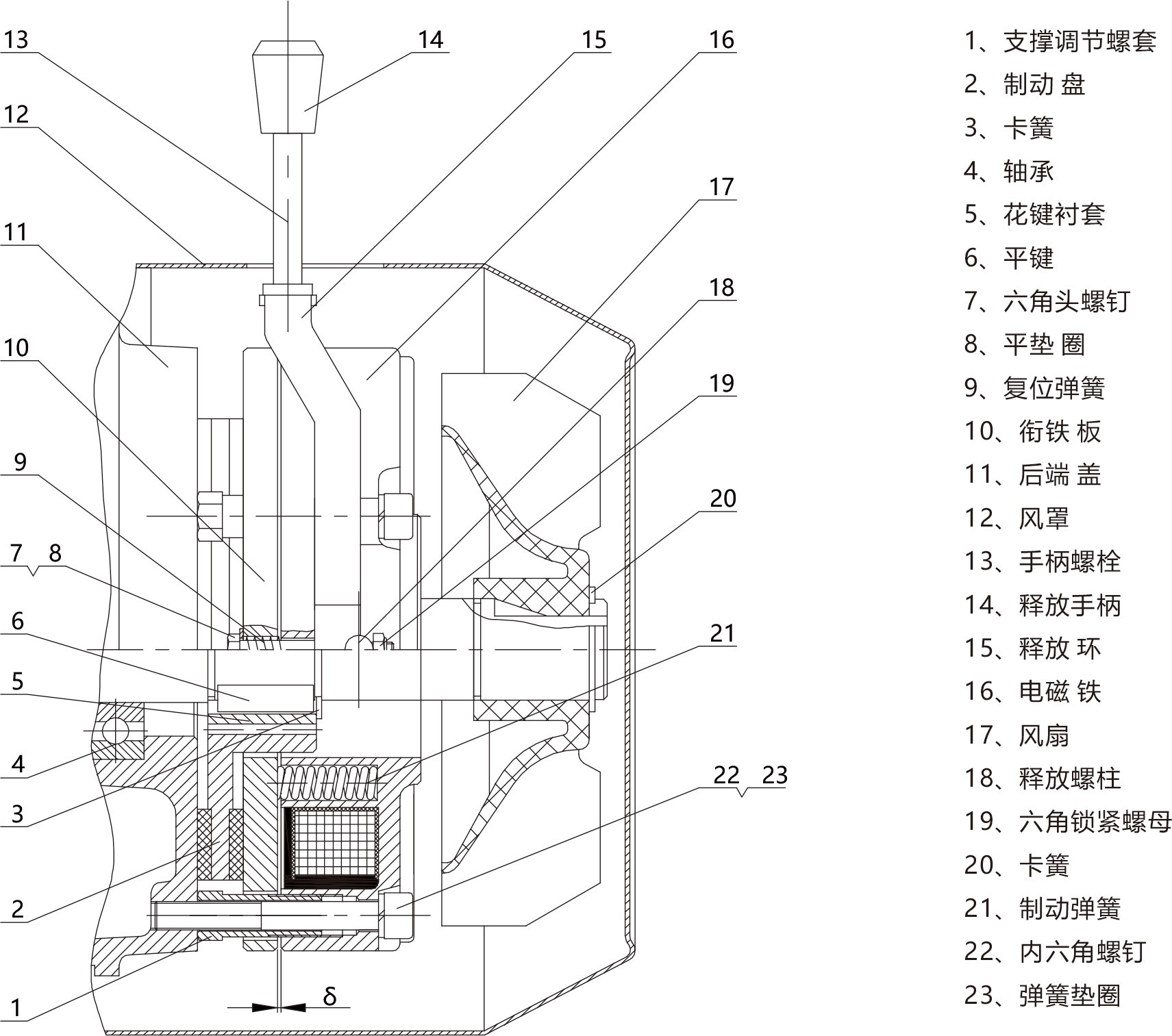

1. Schematic diagram of the structure is as follows:

2. Brake air gap value requirements

3. Air gap inspection

As shown in the structural diagram, the distance between the armature plate 10 and the electromagnet 16 is called the air gap (δ). The normal working air gap (δ) does not exceed the specified working air gap value. When the motor leaves the factory, it is adjusted to the initial working air gap range. After running for a period of time, due to the wear of the friction pads, the air gap (δ) becomes larger, which will affect the normal attraction and braking effect of the brake. Therefore, after the motor has been used for a period of time, according to the large air gap value, select the feeler gauge size to check the size of the air gap (δ). During the inspection, the feeler gauge can be directly inserted into the air gap (δ). If it can be inserted, it indicates that the air gap (δ) is too large and needs to be adjusted.

4. Air gap adjustment

Select the feeler gauge thickness according to the specified initial working air gap value, loosen the hexagon socket screw 16, and rotate the support adjusting sleeve 1 toward the electromagnet by 1-2mm to facilitate air gap adjustment. Place the feeler gauge of the selected size into the air gap (δ) next to the support adjusting bolt, slowly rotate in the hexagon socket screw 16, press the feeler gauge, and then press the support adjusting sleeve 1 against the end cover 8 plane, and pull out the feeler gauge. The hexagon socket screw 16 used for fixing DZK04-75 has three sets. Using the above method, adjust the air gap values on the three sets of screws to the initial working air gap value. The three air gap values should be uniform, and then tighten the hexagon socket screw 16. The hexagon socket screw 16 used for fixing DZK150 has four sets. The debugging method is the same as above.

After the air gap is adjusted, it should be checked again with a feeler gauge to prevent uneven air gap. If there is no standard feeler gauge for air gap adjustment, similar thickness iron sheet can be used instead.

-

Serial Number Malfunction Phenomenon Inspection Location and Method Troubleshooting Measures 1 Brake does not engage (1) Check if the air gap exceeds the specified value;

(2) Use a multimeter to measure the resistance of the excitation coil to check for disconnections.

(3) Check if the rectifier's DC output power supply is normal;

(4) Check if the brake's lead wire connections are loose;

(5) Check if the brake's armature and electromagnet surfaces are clogged with dust after prolonged use;(1) If exceeded, readjust the air gap;

(2) Repair or replace the yoke if there is a disconnection;

(3) Replace the rectifier;

(4) Retighten;

(5) Disassemble and clean the surface of foreign objects;2 Brakes are ineffective or unreliable (1) Friction pad wear, increased working air gap, reduced torque;

(2) Friction pad damage;

(3) Load inertia is too large, exceeding the braking torque;(1) Readjust the air gap (δ);

(2) Replace the friction disc with a new one;

(3) Reselect the model.3 The shaft cannot rotate after manual release (1) Uneven air gap, armature, brake disc, and electromagnet are jammed

(2) The friction disc is stuck by oil (from the gearbox or other locations).

(3) The brake has not been used for a long time, and the friction pads on the motor end cover are rusted.(1) Readjust the air gap;

(2) Disassemble and remove the friction disc, wipe it dry, and then reassemble.

(3) After disassembling and removing rust spots, reassemble for normal operation. -

File Name Size Upload Date Details DZK Series Electromagnetic Brakes 776KB 2021/3/10 Click to Download Operation Video 100M 2021/3/10 Click to Download

Related Products

Message

If you have any questions, please contact us!